Batteries are fine, but what happens when

you can’t charge them? That’s precisely the problem that faces expeditions to

remote places or just those for whom a power socket isn’t readily available.

The solution is a fuel cell, which, as the

name suggests, converts chemical energy into electricity, allowing

battery-based devices to be recharged or run directly from the fuel cell.

The conventional fuels for these devices

are hydrogen, though other flammable gases and liquids like methanol have also

been used successfully. Their technological origins go back to the Victorian

era, but their value was demonstrated by Nasa, which has used fuel cells on its

spacecraft from its earliest manned missions.

The

solution is a fuel cell, which, as the name suggests, converts chemical energy

into electricity, allowing battery-based devices to be recharged or run

directly from the fuel cell.

So could a fuel cell extend your computing

experience? Yes, and in fact there are a few products close to availability. An

MIT spin-off, Lilliputian Systems of Wilmington Massachusetts, has designed a

tiny USB portable charger that uses cartridges containing lighter fluid to

deliver multiple charges to any compatible device.

The prototype device is about the size of a

thick phone, and can offer between ten and 14 full recharges to a typical

iPhone. The price of the device is expected to be less than $200, and each fuel

cartridge just a few dollars.

The fuel cell has impressed those that have

used it, and Lilliputian Systems has not only been able to crack a deal with

BrookStone to distribute its first product, but it also successfully attained

$60m in equity finance from its investors. Brookstone and Lilliputian will make

a formal product announcement in the coming months, so hopefully ts device will

be another option to extend battery life in 2013.

Nanotubes To The Rescue

Carbon nanotube (that odd organisation of

carbon atoms into very useful structures) have many uses, it’s been discovered.

Graphene, as it’s now being referred to, has some especially interesting

electrical properties, some of which might be incredibly useful for battery

technology.

The one that scientists at MIT first

alighted to was to do with the huge surface area that graphene offers, which is

much greater than the graphite that’s traditionally been used. The first

prototype battery demonstrated in 2010 increased the charge by about 30% more

in the same volume. That’s a modest increase but one that is certainly worth

having. The graphene battery also showed some other unique properties to do

with how rapidly charge could be stored and subsequently released.

The

Tesla Roadster, an super-car that’s powered by batteries. It can travel up to

245 miles on a charge and accelerate to 60mph in just 3.7 seconds, but charging

it from a household electrical outlet could take 60 hours!

That allows the batteries to output

increased power, which could certainly be of use in automotive applications,

but it also allows the batteries to charge must faster too.

For problems that need fast charge and

release, the solution has been to use electrochemical capacitors, but these new

graphene batteries provide a whole new layer between conventional lithium-ion

tech and those more extreme devices.

That begs the question: why aren’t we using

this now? Unfortunately, developing commercial solutions working with tubes

that are just one 50,000th of the thickness of a human hair isn’t a priority

for Yang Shao-Horn, an associate professor of materials science and mechanical

engineering. She’s more interested in understanding the chemistry that their

prototypes use, which has yet to be fully understood.

While this work is interesting in the wider

context of battery technology, it probably won’t be what powers a future phone

or PC. Nevertheless, it might demonstrate a path to making recharging less of a

chore and something that could reduce the impact of the limited carrying

capacity we have now.

However, this isn’t the only way that

nanotubes can help our power needs.

Fatter And Faster

It’s worth considering that part of the

battery life issue is the time it takes to charge, because if it didn’t take so

long, then we’d do it more regularly without much concern.

The most common type of battery used in

computing devices is the lithium-ion variety, which has ousted other chemistry

in the past ten years. The technology of this material has some unusual

properties, some that slow down how rapidly it can be charged. What you might

be unaware of when you’re charging your phone is that the battery grows, as a

charged cell occupies more volume than a depleted one.

Also, the battery is charged from the

outside in, so if you make the battery fatter for greater capacity, it takes

even longer to charge.

You can break the cell into small pieces,

but this only helps a little. A new approach by Korean scientists, working at

the Ulsan National Institute of Science and Technology (UNIST), appears to have

solved this problem.

Their solution is amazingly simple: they

take the cathode material (lithium manganese oxide in this case) and soak it in

a solution containing graphite. That creates fibrous conductive pathways

throughout the cathode, allowing power to penetrate the battery much more

easily. It’s then packaged with the graphite anode component as in a normal

battery and you have a device that is identical in performance, other than it

can charge between 30 and 120 times faster.

The catch? The battery is marginally

bigger, which means that it might not be ideal for phones, but it could be used

in laptops, and it’s perfect for traditionally long-charging technology, like

electric vehicles.

More Anode Options

Using graphite as the anode in batteries

goes back to the very earliest battery designs, because it’s cheap and

plentiful, and it works well enough.

Yet much of the research into new battery

concepts has focused on this part of the battery as being the key to superior

performance.

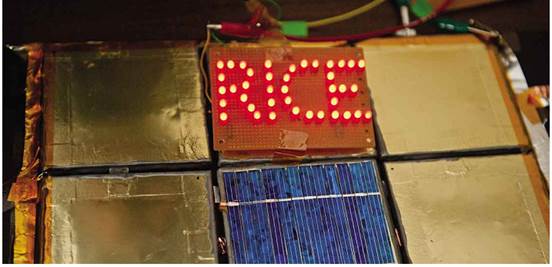

Rice

University has developed a means to spray batteries onto any surface, allowing

them to become part of construction materials

3M, for example, has spent many millions of

dollars and 15 years exploring using silicon as the anode, another cheap and

plentiful material. Why? Well, graphite doesn’t actually store much charge for

its volume, giving a low charge density. The work that 3M has now completed

using silicon boosts the energy density by around 20%, but another 20% extra

power can be had by using new high-energy cathode technology that 3M has also

developed. A total of 40% extra power for the same volume is a significant

improvement and one that most mobile phone and computer users would be keen to

see.

The problem for 3M is that if it doesn’t

get this technology to market soon, it could be overtaken by other developments

in both anode and cathode chemistry.

One of these candidates has been developed

by research company CalBattery, which also uses a silicon anode, but its design

mixes that silicon with graphene.

Dubbed ‘GEN3’ by CalBattery, the anode

substrate it’s developed is a silicon-graphene composite that solves the

problem that many battery chemists have encountered when experimenting with

silicon. Namely, that silicon absorbs lithium better than any other anode

material, but the charge/discharge cycles causes the combination to chemically

alter, providing a short life-span. CalBattery claims to have solved that

problem and in the process delivered triple the power density for the same

volume and mass.

With CalBattery aiming to get products to

market in the next two years, this could be the battery revolution that could

see electric cars become much more practical and phones that work much longer

than a day between recharges.

These are just two of the companies

involved in this line of research, but numerous other companies are investing

heavily in battery research, including General Motors and Envia Systems, who

together are aiming to sell electric vehicles with 200-plus mile ranges in the

next four years. Tesla Motors is also working with PolyPlus, and their

lithium-air and lithium-water battery technology aiming to get 500 miles of

charge in a car. With that level of power density, surely making a phone or

laptop work for longer isn’t just a pipe-dream?