With the launch of chipsets

incorporating USB 3.0 support, this latest USB interface standard is now

becoming widely available on board level and system platforms. How long,

though, will end-users in the industry have to wait before they can benefit

from this technology in OEM products like vision systems? And how does the cost

situation look?

USB 3.0 is emerging as the new interface

standard for fast peripherals. This need is evident in the field of appliances

that can generate added value from this nominal 5Gbps performance boost beyond

the maximum USB 2.0 performance (nominal 600 Mbps). With up to 2400 Mbps of

usable data rate, it achieves a 7.5 times faster throughput than with USB 2.0

(320 Mbps).

With

the launch of chipsets incorporating USB 3.0 support, this latest USB interface

standard is now becoming widely available on board level and system platforms.

Applications that profit from this

performance boost are, for example, fast and high-resolution printers and

scanners, or mass storage. Further examples are high-resolution rear-view

cameras for all-round visibility in trucks, high-resolution test and measurement

devices, and a vast number of vision applications like camera-supported pick-and-place

(PnP), intelligent surveillance systems in the traffic technology, or digital

microscopes, to name a few.

USB 3.0 focus market vision systems

In addition to Gigabit Ethernet, today in

the vision area it is already becoming apparent that USB3 vision for

close-range applications of up to five meters will evolve into the leading

standard. The USB3 vision standard is entirely based on the USB 3.0

specification and additionally inserts GenICam - a generic programming

interface that simplifies application porting and promotes interoperability of

USB devices from different manufacturers. Customers benefit not only from the

actual vision specifications but also from the advantages of USB 3.0 itself.

Advantages of USB 3.0

Apart from the immense performance boost in

comparison to USB 2.0 - the USB 3.0 bus is backwards-compatible to USB 2.0 and

1.1. It further excels due to its simple cabling that provides power and data

communication in one cable, which, in turn, serves to reduce installation work.

Also, manufacturers are making their peripheral devices PnP-capable, so all you

need for this is defined 'on the wire.' That results in significantly less implementation

work for the system integrator.

The

USB 3.0 bus is backwards-compatible to USB 2.0 and 1.1.

What's more, in future, USB 3.0 will be

found on nearly all industrial computer platforms as USB 3.0 support will immediately

be integrated into the chipsets - and presumably for a very long time to come.

That saves a great amount of hardware development costs in comparison to

standards like Camera Link, even though this standard depending on the

manufacturer can process an 80-bit video track with up to 6.8 Gbps or 5400

Mbps, and continues to be supported via PCI- or PCIe-based frame-grabber

cards.

Consumer market pushes USB 3.0 cameras

If you observe the consumer camera market

which is already switching to USB3.0, it becomes clear that the corresponding

embedded camera technology can be used for close-range industrial

applications. The main advantages therefore are reduced costs with added

performance, more comfort and higher integration. Also, considering the fact

that in video applications the processing of a multitude of tasks can be

handed over to a GPU rather than to a frame grabber, in this area and in the

long term, the PC ecosystem offers the more promising solution for a large

range of new designs.

USB 3.0 now available in the chipset

The most significant cost factor in PC

implementation of USB 3.0 is the availability in the chipset. Since the launch

of third-generation Intel Core processors and AMD Embedded R-Series

processors, the new interface standard USB 3.0 has been integrated into these

manufacturers' chipsets and thus is available as a standard on embedded board

and system level, which proves immense cost-saving.

USB

3.0 now available in the chipset

USB 3.0 implementations by OEMs

Widespread introduction into the industrial

environment has not yet taken place and in terms of embedded PC technology can

be seen as still in its infancy, as the USB 3.0 chipsets have only just been

launched and still have to be designed-in.

On the other hand, a relatively inexpensive

way to realize this is not really available: At present, third-generation

Intel Core processors are not yet available in the inexpensive Celeron

variants. Consequently, a corresponding inexpensive implementation does not

exist. And the AMD R-Series must first overcome design-in obstacles. So bearing

this in mind, it will take a certain amount of time for inexpensive OEM

implementations to appear on the market, unless alternative solutions are

developed in the meantime with, for example, USB 3.0 bridges.

Current most cost-effective USB 3.0

implementations

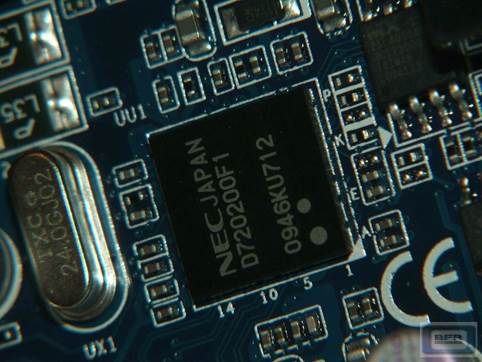

This can be achieved, for example, with

Celeron processors of the second-generation Intel Core (codenamed Sandy

Bridge) and an additional NEC bridge for USB 3.0. Using a method like this,

solutions ready for serial production have been realized since the beginning of

2011. One such solution was a COM Express type 6-based computer-on-module (Fig.

1). It offers developers a fast time-to-market for this highly attractive

interface. This design with USB 3.0 is one of the first embedded implementations

which customers have been able to use before the introduction of chipsets that

support USB3.0 and has thus enabled them to accelerate time-to-market of USB

3.0 platforms.

The

COM Express basic computer-on-module with type-6 pinout comes with 1x1.00GHz to

2x1.60GHz scalable Intel Celeron processor and HM65 PCH. With two optional USB

3.0 interfaces, it offers an especially cost-efficient USB 3.0 configuration,

which has been available since the beginning of 2011 for early adoptors, and is

fitted with the NEC USB 3.0 Bridge

The importance of such early availability

of latest technologies is especially crucial for innovative companies, as

when the chipsets are launched, end-user awareness and the demand for USB 3.0

increase suddenly. This gives a real competitive edge to OEMs who want to

deliver USB 3.0 implementations parallel to chipset launches. That is possible

only if you already have this type of technology ready for mass production.

First customer implementations with USB

3.0

A first customer using the module, which

works with a USB 3.0 bridge on a solution with Intel Celeron processor of the

'Sandy Bridge' generation, will present a first, highly integrated solution at

the Vision 2012 which uses cost-efficient USB 3.0 camera modules. Another

customer is currently developing a traffic surveillance solution and a third is

creating a box PC for SFF vision applications, to name just three examples in

the vision segment.

With

twelve modules and boards in the form factors COM Express, Mini-ITX, Flex-ATX

and CPCI, AMC as well as VPX, there is already a wide standard assortment of

latest solutions based on Intel or AMD processors. These solutions already have

USB 3.0 integrated in the chipset and can be adapted to suit customers’

specifications

All these applications are projects that

promise technological leadership in the corresponding segment - for example, in

combination with M2M solutions. Their competitive advantage time-wise in

comparison to chipset- based solutions is at least the design-in phase or

probably even longer, assuming that in future one wants to opt for using Ivy

Bridge-based Intel Celeron processors.

USB 3.0 technology platforms for today

and tomorrow

OEMs who did not start designing at the

beginning of 2011, now, of course, have a much wider choice. To start using

this technology cost-efficiently, today, they will nevertheless either have to

use the Celeron version with USB 3.0 bridge, as it will be a cost-efficient

solution in the long term, or the new AMD Embedded R-Series processors, if

attractive integrated 'embedded graphics' are required along with attractive

pricing. It goes without saying that if inexpensive solutions are required,

the third-generation Intel Core processors can be designed-in, in order to put

OEMs in a position to directly move to the same platform when the Intel Celeron

processor version presumably becomes available at a later date. But for

high-end solutions, there is no way around the third-generation Intel Core

processors. Some customers will also be looking for a solution based on ARM

processors and USB 3.0.

Hardware integration services for USB

3.0 solutions

All these solutions are already possible

today. And, for all these platforms, embedded computer manufacturers offer

standard products, custom designs and corresponding hardware integration

services. So customers can concentrate on what they do best - the application

itself. The corresponding application-ready embedded computing platforms and

the matching hardware integration services including software support for, say,

drivers or migrations are provided by a partner. The partner on the basis of

serial standard products delivers fast and efficient support for individual

implementations in a very close and trusting development partnership. In this

way, bottlenecks can very efficiently be done away with.

Along

with modular AMC- and VPX-based systems, with the KISS 2U server family, first

proofs-of-concept on system level have already been realized. The servers are

equipped with a Flex ATX motherboard and offer several PCIe 3.0 interfaces as

well as a PCI port along with USB 3.0. In comparison to designs with

second-generation Intel Core processors, the KISS server in 2U rack mount

format offers up to 20 per cent more computing performance, 50 per cent more

graphic performance and an increase of up to 40 per cent in

performance-per-watt