The beauty in the Millenniata technology is

that it is also affordable for normal users. An entire series of disc writers

from popular models can burn the discs. These drives have a special adapted firmware

which recognises M-discs, and the laser power is set correspondingly. Other

drive manufacturers such as Dell want to follow. Blank M-discs are available at

Amazon in spindles of ten for $75. Your data is this safe within reasonable

cost limits.

From the durability point of view, M-disc

has a clear edge over burnt disks. A test carried out by the US Navy proved

that no other type of optical disc else was as reliable. Data was lost even

with discs from the quality brand Taiyo Yuden.

We exposed an M-disc to strong light

radiation for 72 hours in a UV chamber in our test laboratory. It also

withstood this like a Glass MasterDisc. In contrast, cheap everyday discs from

Sony all broke down, and even Verbatim's expensive "Archival Grade"

blanks suffered from a nearly 300 percent increase in read errors.

An

M-disc from Amazon. A spindle of 10 costs approximately $75. The discs can be

written with a few reasonably priced disc writers from known brands.

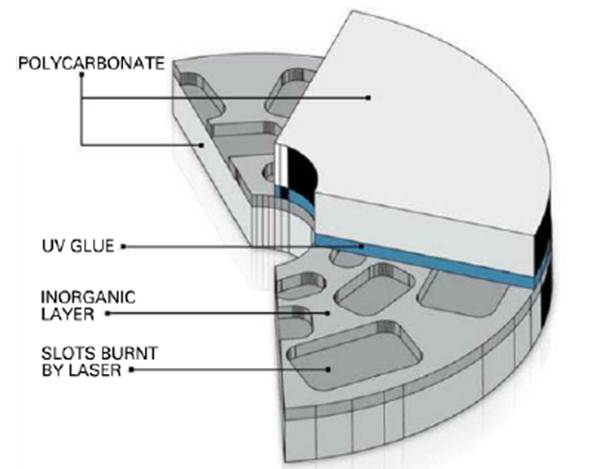

Structure of an M-disc

The data is in a layer similar to a stone,

made of inorganic material. The laser burns slots into this layer when writing.

In the endurance test: branded DVDs don't stand a chance

The US navy tested burnt DVDs against the

M-disc. The discs were stored for 24 hours at 85 °C and 85 percent humidity.

Most of them were unreadable, but the M-disc survived.

GlassMasterDisc: etched on glass

Everything is written on a disc made from a

special glass. These last about 1,000 years, whether stored on the earth or in

outer space.

Glass is more resistant to damage than even

the M-disc with its layer of rock. Glass is commonly known for being extremely

delicate, but the German startup Syylex offers the GlassMasterDisc, which

eliminates one weak point of the M-disc: the materials which enclose the write

layer are both made of polycarbonate. The National Institute of Standards and

Technology (NIST) in the USA estimates its durability to be 1,000 years—which

is where the name Milleniata comes from. But the polycarbonate layers can

endure only short-term temperature fluctuations such as a dip in liquid

nitrogen or boiling water, but it melts at exposure to 220°C and above. Thus,

only the write layer of an M-disc remains intact and can withstand temperatures

of up to 500°C on its own.

One

must place a custom order for GlassMasterDiscs. Production of the disc takes

about five days. It costs at least $183 per disc, including a complete quality

check.

Resistant to radiation and heat

If you want durability as well as

protection against natural disasters, burning and radiation, you must switch to

glass. This is no ordinary glass, though - Syylex uses a material which is also

used in large-scale chemical industry plants to store or channel acids and

other aggressive substances. It can be compared to Duran borosilicate glass

whose resistance surpasses that of most other materials. Only hydrofluoric

acids and strong alkalines can corrode it, and that too at temperatures of over

100°C. It remains stable up to 500°C and becomes soft from 850°C onwards. Such

a glass disc withstands even the conditions of outer space i.e. temperatures at

absolute freezing point and high doses of radiation. The Japanese probe Ikaros

started off in the direction of Venus in 2010 and has such glass DVDs on board.

Sadly you cannot burn this type of disc yourself, but can only place an order

for it. Production takes five to ten days at Syylex after sending in the data,

and costs about 150 Euros per disc.

Glass is the traditional component of the

production process of pressed discs such as DVD ROMs. At the time of

replication, a Glass Master serves as a negative for subsequent copies. The

first step of production for a Syylex disc also resembles the creation of a

Glass Master (see left). A reflection layer is laid on so that the disc is

readable in any commonly available disc drive. Finally, a second glass disc is

applied with special UV-cured glue to ensure that the finished disc cannot be

broken without considerable difficulty.

Besides the Japanese field test in outer

space, even the French Laboritoire National de Métrologie Et d'Essais has

examined the durability of the glass disc. Different disc types were stored at

a temperature of 90°C and humidity of 85 percent in test more intense than that

required by the ECMA standard. Pressed DVD ROMs were unreadable after maximum

375 hours; burnt discs had already broken down – only the glass disc held out

for the entire 1,500 hours.