Bored with your USB thumb drive’s

functional appearance? Antony Leather shows you how to make your own

While they can be immensely useful, USB

thumb drives often look bland. This is especially true of the generic,

bargain-basement types, which are often housed in unadventurous plastic boxes.

Thankfully, there are ways to add some pizzazz, or even create your own custom

case. You can create a mould and use casting resin to create practically any

shape of USB flash drive you want, and then add dyes or glitter to make really

it stand out.

Alternatively, you can also go the whole

hog and use a random object such as a LEGO brick or Micro Machine as the housing

for your creation. As this is Custom PC, we decided to dust off an old LGA775

Core 2 processor and put it to use as a USB flash drive. Now that even 32GB USB

flash drives will set you back less than $22, there’s little reason not to give

this a try.

Tools you’ll need

·

Clear plastic casting resin (250g for casting

one USB flash drive)

·

Plasticine or wax and polystyrene foam

Most art supply stores

·

Epoxy resin (for making a CPU flash drive)

Most hardware stores

Make a cast-mould thumb drive

1. Pick the right flash drive

If you’re keen on obtaining a glowing

effect through transparent acrylic then it’s very important to choose a USB

flash drive that has a powerful access LED. Some don’t have an access LED at

all, while others have a point light, rather than a bright LED. Shop around

until you find one that suits your needs.

2. Decide on colors and design

There are plenty of options when it comes

to creating your custom USB thumb drive. You can use clear or opaque casting

resin, and also use dyes to give the otherwise clear finish a colored tint. You

can also add glitter, pieces of metal or other objects to jazz up your design a

little more.

3. Remove enclosure and inspect PCB

Dismantling a USB flash drive is usually

pretty easy, despite the fact that most are sealed units. Ours just needed a

little persuasion with a small screwdriver, but be careful not to damage the

PCB. Once you’ve removed it, plug it into a PC to make sure it still works.

4. Plan your casting mould.

There are several ways to create the shell.

You can use sections of wood to create a cube-shaped mould, or Plasticine or

wax with a polystyrene cast to create a mould instead. We used high-density

polystyrene foam to create a 1:1 scale model of our shell. Use sandpaper and a Stanley knife to trim the foam to shape.

5. Create a mould

The foam enables you to create a mould

using Plasticine, into which you can pour the casting resin. It’s easy to work

with Plasticine, so you can create many shapes and sizes of enclosures. Once

you’ve moulded the Plasticine around the foam, start digging out the foam,

taking care not to deform the mould.

6. Insert USB Thumbdrive

The easiest way to suspend the USB

Thumbdrive is to simply insert it into the wall of the Plasticine. As it’s very

small and light, the Plasticine should be strong enough to hold it in place

while the resin sets. It’s worth filling the USB connector with spare foam, as

the Plasticine will dig into the connector as you insert it.

7. Mix casting resin

The casting resin usually doesn’t start to

set for at least 20 minutes after mixing, but you should still prepare your

working area and mould, so that you’re ready to pour the resin directly into

your mould as soon as possible, just to be safe. Use a plastic tub to mix the

resin, following the guidelines about the mix ratio.

8. Add glitter to casting resin

We decided to add some glitter to the

resin, which will reflect the LED light and add a little pizzazz. Quickly add

this, or your chosen material, and then mix the resin. It’s important to mix it

thoroughly but not too vigorously, as this can introduce air bubbles, which

will be trapped in the resin.

9. Pour casting resin

Once you’ve mixed the resin, give your

mould a once-over, making sure the USB thumb drive is still centred in it, and

that the mould is resting on a flat surface. You can then pour the casting

resin into the mould.

10. Allow to set and remove mould

Don’t be tempted to mix the resin around to

fill the corners, as you’ll run the risk of the edges becoming frayed instead

of straight gravity will do its work. Setting times will vary depending on the

type of casting resin, but it’s usually best to wait 24 hours before removing

the mould from your new USB thumb drive.

Make a CPU thumbdrive

1. Choose your object

Rather than using casting resin, you can use

an existing object to house your USB thumb drive. LEGO bricks work well, as do

Micro Machines, but we had an old Core 2 CPU lying around collecting dust, so

we decided to put it to good use.

2. Measure the PCB

Before you do anything, measure up the PCB and

your chosen object to make sure everything will fit. There isn’t a lot of room

under the HIS of a CPU, so make sure there are no tall components on the PCB.

You don’t need a large, powerful LED either, as the hole of the PCB will be

enclosed within the CPU.

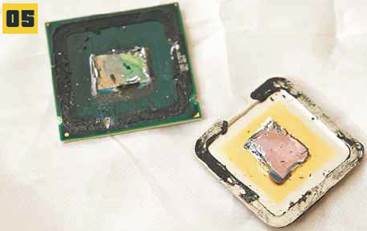

3. Remove adhesive

You’ll need to remove the HIS first, by

running a scalpel around the edges of the CPU to cut away the adhesive. This is

exactly the same as the method used in last issue’s Ivy Bridge modding guide.

It will help to hold the CPU in a pair of pliers, using kitchen roll to prevent

scratches.

4. Remove the IHS

Most CPU cores are held to the IHS using

solder, and this can make it tricky to remove them from each other. If prying

open the IHS with a small screwdriver doesn’t work, it’s worth investing in a

mini-blow torch to heat the solder. These only cost a few pounds and will do

the job in seconds.

5. Make room for the thumb drive

You’ll need to commit heresy and remove the

CPU core, using either a Dremel with a cutting or grinding disc, or a

screwdriver and knife to gradually cut away at it. You may also need to cut a

recess in the CPU package, and you’ll need to cut a small section of the IHS to

allow the thumbdrive to pass through it too.

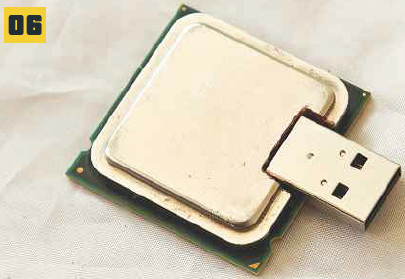

6. Stick it together

Line up the thumb drive on your CPU, apply

a generous amount of epoxy to the PC and replace the IHS. It’s worth placing a

heavy object on the CPU to ensure it sets tightly together. Epoxy will need an

hour or so to set, but it’s best to leave it overnight before you try inserting

it into a USB port just to be sure.